In 1860 Etienne Lenoir

employed the electrical light plug in his petrol engine, the initial internal combustion piston engine. Lenoir is mostly

credited with the design of the light block. Some references account Edmond Berger, an

African American thought to have immigrated from Togo, with producing the light block in early

1839, though records reveal he did not have a patent for his device. First patents for light plugs

included those by Nikola Tesla (at America document 609,250 for the combustion timing

organization, 1898) , Frederick Richard Simms (UK 24859/1898, 1898) and Robert Bosch (GB

26907/1898 ). But the design of the early commercially possible high-voltage

light block as part of the magneto-based ignition method by Robert bosch's operator Gottlob Honold in 1902 made

possible the process of the spark-ignition engine.

Engine burning is offered by two engine-driven magnetos,

and two light plugs at each container. This good Magneto fires the lower good

and the top left light plugs, and the remaining Magneto fires the lower left

and top just spark plugs. Regular process is conducted with both magnetos

because of the more thorough combustion of the fuel-air mix with dual ignition.

Ignition and starter process is operated by the circular type controller placed

on the left-hand switch and control panel. This shift is labeled clockwise,

OFF, R, L, BOTH, and turn. This motor should be controlled on both, magnetos

(both point) except for Magneto checks. The R and L positions are for

determining uses and emergency function but. When the shift is rotated to the

spring-loaded first point, (with the student shift in this ON point) , the

starter contactor is energized and the starter can turn the engine. When the

shift is released, it will automatically move to that BOTH points.

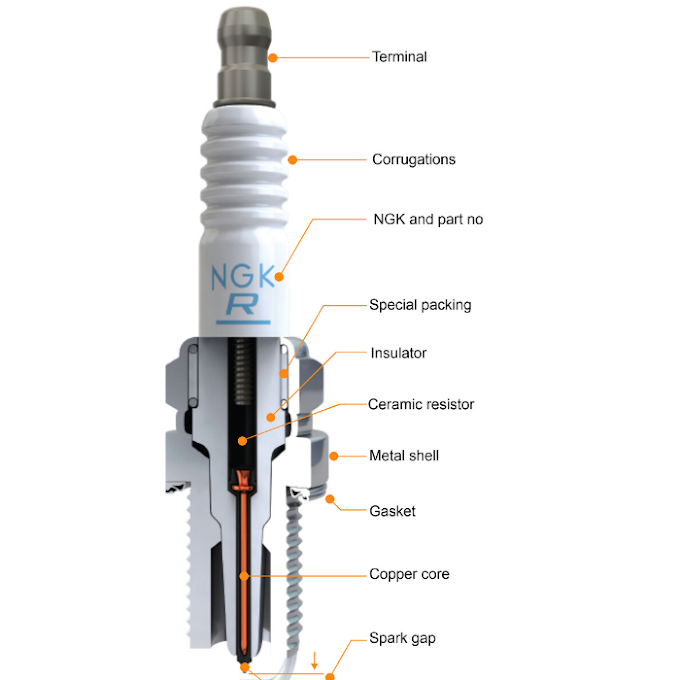

The important portion of this insulator is typically

given from sintered alumina (Al203 ), (basic cognition " author ".

Globaldenso.com.) A really difficult ceramic material with high dielectric

power, printed with the maker's name and identifying markers, so glazed to

better resistance to cover light tracking. Its major purposes are to provide

automatic assistance and electric protection for the middle electrode, while

also offering an long light line for flashover security. The long part,

especially in engines with deep recessed plugs, helps expand the station over

the cylinder top so as to make it more readily available.

The light plug is said to be " warm " if it is

a greater energy insulator, holding more energy at the end of the light plug.

The light plug is said to be " frozen " if it will conduct more

energy out of the light plug tip and decrease the point's temperature. Whether

the light block is ' ' hot " or cold this called the temperature range of

the light plug. The temperature range of the light block is typically defined

as the figure, with some makers using ascending figures for hotter plugs, and

others doing the opposite - using ascending numbers for colder plugs.

This temperature range of the light block is impacted by

the structure of the light block: The types of materials used, the size of

insulator and the surface area of the plug exposed within the combustion

chamber. For regular purpose, the choice of the light plug heat range is the

difference between holding the point warm enough in idle to keep fouling and

cold enough in maximum force to prevent pre-ignition or engine knocking.

The explanation of pre-ignition is the firing of the

fuel/air 'cost prior to the light plug fire. Pre-ignition caused by other

burning source , e.g., the overheated light plug tip, carbon deposits in the

combustion chamber and, rarely, the burnt gas device; all function as a glow

plug to ignite the charge. Keep in mind this following repetition when examining

pre-ignition. The commission enters the combustion chamber as the piston hits

BDC for consumption; the piston next reverses way and begins to tighten the

cost.

Tags

0 Comments